AI Factory Layout Planner

AI-powered factory layout optimization within YugmaXR platform. ML algorithms suggest equipment placements minimizing material flow and maximizing utilization. Real-time constraint validation ensures safety compliance. Teams collaborate in VR to review layouts, annotate concerns, and iterate. Exports to AutoCAD and Process Simulate.

⚡ Challenges

- •Multi-objective optimization

- •Real-time constraint validation

- •VR collaboration at scale

✓ Outcomes

- ✓15% improvement in material flow efficiency

- ✓4x faster layout iterations

- ✓Used in 8 factory planning projects

📖 Full Details

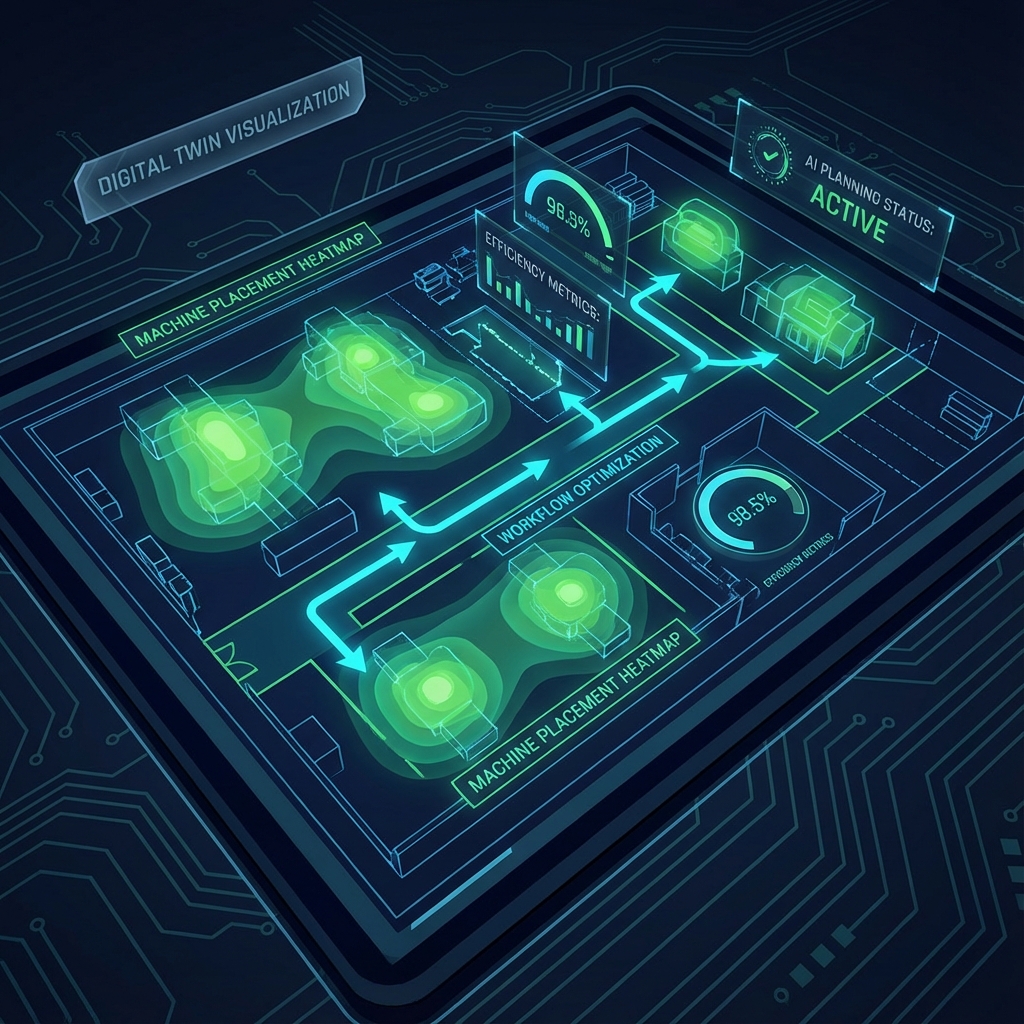

This AI-powered factory layout planning tool within YugmaXR revolutionizes how manufacturing engineers design production facilities. Using machine learning optimization, the system suggests equipment placements that minimize material flow distances, maximize space utilization, and ensure safety compliance—all within an immersive 3D environment.

The planning workflow begins with importing facility dimensions from CAD or defining spaces manually. Equipment libraries contain accurate 3D models with metadata including footprint, utility requirements, maintenance access zones, and safety clearances. Users place initial equipment positions, and the AI engine analyzes the configuration.

The optimization algorithm considers multiple objectives: material flow efficiency (calculating transport distances for defined work sequences), operator walking distances, maintenance access, forklift pathway clearances, and emergency egress requirements. Constraint satisfaction ensures all safety regulations are met while searching the solution space for improved layouts.

Visualization modes include flow diagrams overlaid on 3D layouts, heat maps showing utilization density, and animated simulations of material transport. Collision detection highlights placement conflicts in real-time as users modify designs.

Collaboration features allow distributed engineering teams to review layouts simultaneously in VR, annotate concerns, and iterate toward consensus. Layout versions are tracked with full history, enabling rollback and comparison.

The system exports finalized layouts to AutoCAD and CAD formats for integration with architectural and MEP (Mechanical, Electrical, Plumbing) design workflows. Integration with Process Simulate enables handoff to virtual commissioning phases.